Driving and Braking System of Large Belt Conveyor

Release time:

May 17,2018

For the failure of the hydraulic system of on-site construction machinery, according to the working principle of the hydraulic system and the sequence of the power components-control components, the cause of the failure can be analyzed forward on the system diagram. For example, the working weakness of the excavator boom is considered to be caused by the decrease of oil pressure or flow rate. From the system diagram, the possible factors causing the pressure drop are: ① oil tank, such as lack of oil, the oil suction filter is blocked and the vent hole is not smooth; ② the hydraulic pump leaks, such as the increase of the matching clearance of the hydraulic pump plunger pair; ③ the pressure adjustment of the main safety valve on the control valve is too low, and the configuration of 30 is analyzed, and the relevant problems are carried out

For the failure of the hydraulic system of on-site construction machinery, according to the working principle of the hydraulic system and the sequence of the power components-control components, the cause of the failure can be analyzed forward on the system diagram. For example, the working weakness of the excavator boom is considered to be caused by the decrease of oil pressure or flow rate. From the system diagram, the possible factors causing the pressure drop are: ① oil tank, such as lack of oil, the oil suction filter is blocked and the vent hole is not smooth; ② the hydraulic pump leaks, such as the increase in the matching clearance of the hydraulic pump plunger pair; ③ the pressure adjustment of the main safety valve on the control valve is too low, and the configuration of 30 is analyzed. Elaborate.

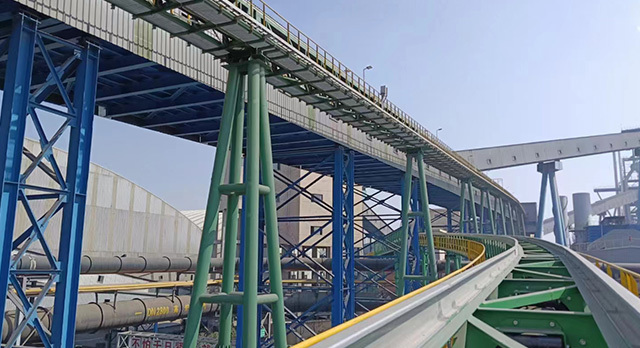

For the belt conveyor mainly for flat transportation and upper transportation, it is mainly to solve the driving problem, while for the belt conveyor mainly for the following transportation, it is mainly to solve the braking problem. Because when the lower conveyor belt is running on load, the load drags the motor to run, and the motor is in a power generation braking state. Once the motor loses power and is not equipped with a suitable braking system, the lower conveyor belt will speed faster and faster, causing a flying car accident. The driving system and braking system of the large belt conveyor are discussed below.

1 the drive system of large belt conveyor for flat or upper belt conveyor, the drive system is generally composed of electric motor, hydraulic coupling and reducer. Due to the limited torque type liquid or serious internal leakage; ④ The setting pressure of the overload valve of the boom hydraulic cylinder is too low or the internal leakage is serious; ⑤ The oil return circuit is not smooth, etc. Taking into account these reasons, according to the existing inspection results to eliminate some factors, narrow the scope of the fault, until the fault point is found and ruled out.

In the fault diagnosis of the hydraulic system of construction machinery in the field construction, according to the working principle of the hydraulic system, we should master some laws and common sense, and analyze whether the fault is early onset or gradual onset. If it is early onset, it is mostly improper adjustment. If it is gradual onset, it is often caused by component wear, corrosion, fatigue and aging. Second, it is necessary to analyze whether it is a vulnerable part or a non-vulnerable part. If the moving parts under high frequency and heavy load are hydraulic components prone to failure, such as plunger pair, oil distribution plate pair, variable servo and hydraulic cylinder of hydraulic pump, etc., while the components are at low frequency, light load or basically relatively static, it is not easy to malfunction, such as reversing valve, sequence valve, slide valve, etc. After mastering these laws, it can play a positive role in quickly judging the fault site.

Key words:

Next Page

Next page:

Recommended News

HUADONG Machinery

Add: No.8, Yanghuan Road, High-tech zone, Jiangyin, Jiangsu, China

Tel: 86-510-86195578

Mobile: 86-13915232058 86-15061750668

E-mail: sales@hdconveyor.com

Official Website