Selection and Function of Roller Conveyor

Release time:

May 17,2018

The roller conveyor mainly relies on the arrangement of the rollers to form a complete conveyor line. It can not only transport materials separately, but also combine with other conveying equipment to form a complex conveying system. The main components of the conveying equipment in the drive roller, it is to rely on the friction between the conveyor belt to drive the conveyor belt to run. The drive roller in the roller conveyor can be divided into light, medium and heavy according to the size of its bearing capacity, and the diameter of the same roller has several different shaft diameters and center spans for selection. 1, light roller: bearing aperture is usually 80-100mm, shaft and hub one

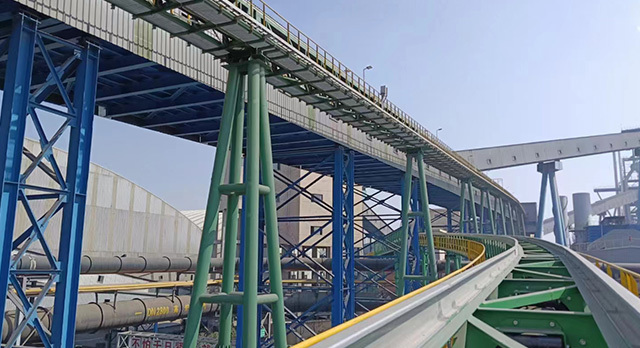

The roller conveyor mainly relies on the arrangement of the rollers to form a complete conveyor line. It can not only transport materials separately, but also combine with other conveying equipment to form a complex conveying system. The main components of the conveying equipment in the drive roller, it is to rely on the friction between the conveyor belt to drive the conveyor belt to run. The drive roller in the roller conveyor can be divided into light, medium and heavy according to the size of its bearing capacity, and the diameter of the same roller has several different shaft diameters and center spans for selection. 1. Light roller: the bearing aperture is usually 80-100mm, and the shaft and the hub are generally single-key connected single-plate welded cylinder structure. 2. Medium-sized roller: the bearing aperture is generally 120-180mm, and the shaft and hub are mostly connected by expansion sleeve. 3. Heavy-duty roller: the bearing aperture is mostly 200-220mm, the shaft and the wheel hub are mostly expansion sleeve connections, and the cylinder is cast-welded structure, with one-way shaft output and two-way shaft output options. In order to increase the coefficient of friction, usually on the surface of the steel smooth surface roller, add a layer of rubber bottom surface with herringbone groove, this kind of roller has direction, can not reverse operation. The roller conveyor uses a herringbone groove rubber-coated roller. Even if it works in wet occasions, the friction series reduction will be very small, because the groove can interrupt the water film and does not accumulate water. At the same time, when the conveyor belt is in contact with the roller, the conveyor belt The surface can be squeezed into the groove. Many factories, the production environment is humid, power consumption is large, usually choose herringbone groove rubber roller. The drive roller in the roller conveyor is divided into single-point drive mode, which can be divided into single-roller drive and double-roller drive. Single-drum drive is mostly used on conveyors with little power. Double roller drive is mostly used for high-power conveyors, because it is not only compact, but also can increase the surrounding angle to increase the traction that the roller conveyor drive roller can transmit. In addition, the use of dual-drum drive can not only use multiple motors to drive separately, but also use gear transmission to make the two rollers run at the same speed. The transmission roller structure of the roller conveyor has steel plate welding structure, cast steel and cast iron structure. We can choose the roller structure suitable for ourselves according to the actual needs and production environment.

Key words:

Previous Page

Previous Page:

Recommended News

HUADONG Machinery

Add: No.8, Yanghuan Road, High-tech zone, Jiangyin, Jiangsu, China

Tel: 86-510-86195578

Mobile: 86-13915232058 86-15061750668

E-mail: sales@hdconveyor.com

Official Website