17

2018-05

Analysis on Prevention and Treatment of Conveyor Belt Deviation

Conveyor belt deviation is a fault often encountered in the process of conveyor use, and it is also a headache for customers. How to prevent and eliminate the fault of the conveyor belt deviation? First check the cause, and then one by one "the right medicine". Preventive measures to 1. the deviation of the conveyor belt (1) improve the installation quality (2) improve the quality of the conveyor belt joint;(3) strengthen the inspection and maintenance of the tour (4) to ensure that the loading is not biased;(5) to ensure that the cleaning device is normal. On-site treatment method for 2. conveyor belt deviation (1) automatic drag roller deviation adjustment: when the conveyor belt deviation range is not large, a self-aligning drag roller can be installed at the conveyor belt deviation. (2) Appropriate tension and deflection adjustment: when losing

2018-05-17

17

2018-05

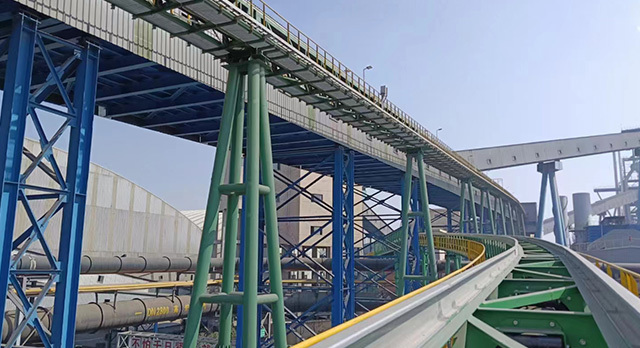

Driving and Braking System of Large Belt Conveyor

For the failure of the hydraulic system of on-site construction machinery, according to the working principle of the hydraulic system and the sequence of the power components-control components, the cause of the failure can be analyzed forward on the system diagram. For example, the working weakness of the excavator boom is considered to be caused by the decrease of oil pressure or flow rate. From the system diagram, the possible factors causing the pressure drop are: ① oil tank, such as lack of oil, the oil suction filter is blocked and the vent hole is not smooth; ② the hydraulic pump leaks, such as the increase of the matching clearance of the hydraulic pump plunger pair; ③ the pressure adjustment of the main safety valve on the control valve is too low, and the configuration of 30 is analyzed, and the relevant problems are carried out

2018-05-17

HUADONG Machinery

Add: No.8, Yanghuan Road, High-tech zone, Jiangyin, Jiangsu, China

Tel: 86-510-86195578

Mobile: 86-13915232058 86-15061750668

E-mail: sales@hdconveyor.com

Official Website